History of PJSC KuibyshevAzot

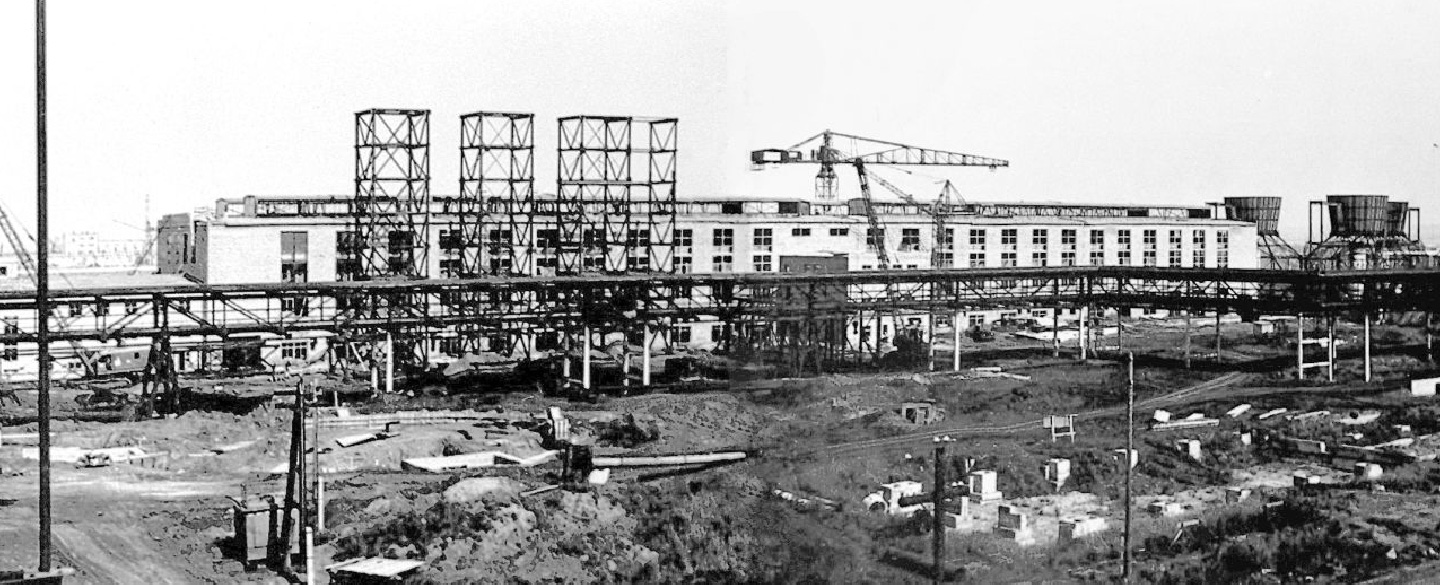

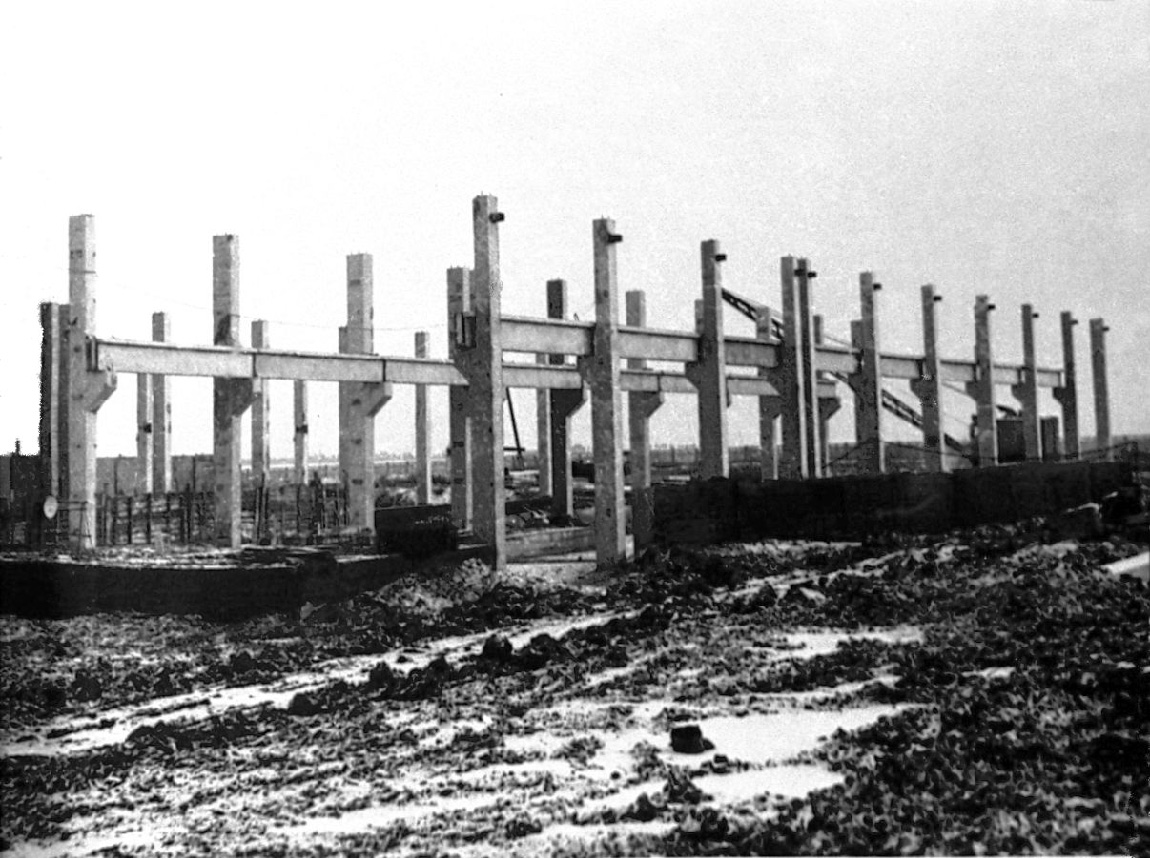

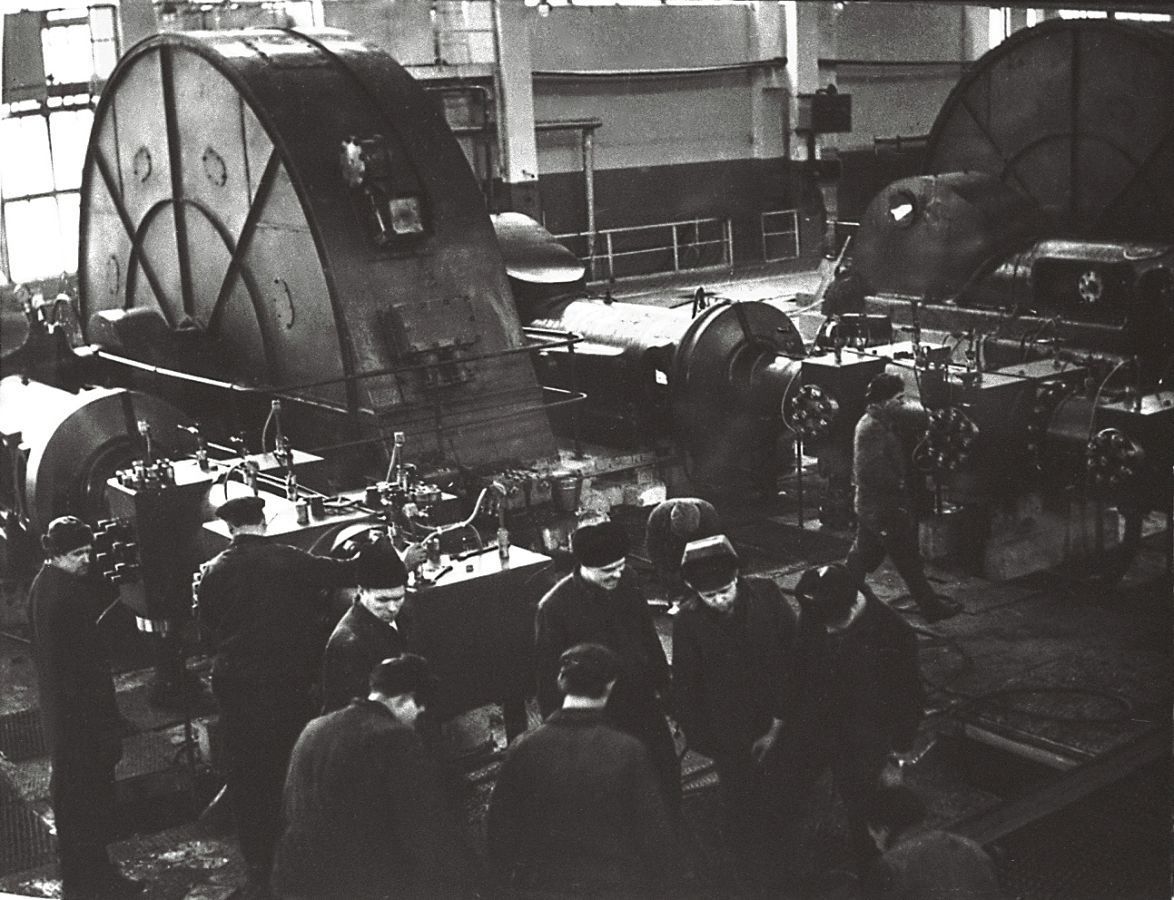

Construction of Kuibyshev Nitrogen Fertilizer Factory (KATZ) began in 1961. In 1966, the enterprise started operating according to the complete technological scheme. August 23, 1966 is considered factory’s official date of birth. KuibyshevAzot Production Group was founded in 1975, with KATZ as a parent enterprise, comprising Togliatti Nitrogen Plant (ToAZ), Azotremmash and Transammiak. In 1981, as a result of reorganization, these companies became separate legal entities. In 1991 KuibyshevAzot became a leased enterprise, and then in 1992, KuibyshevAzot Closed Joint Stock Company was founded.

During the crisis of the 1990s, when there was a change in the economic and political model of the country, the Company, unlike many other factories, was able to keep the production of marketable products at the pre-reform level and retain a highly skilled stable team. The beginning of the new century became a time of rapid growth for KuibyshevAzot. As part of the Company's development strategy aimed at increasing the share of products with higher added value, an advanced caprolactam processing project has been implementing since 2000. Within that project the Company has built a complex for production of polyamide 6, technical yarn and cord fabric at the industrial site in Togliatti; commissioned engineering plastics production in China; acquired assets to produce industrial technical and textile yarns, cord fabrics in Kursk; and polyamide fabrics in Balashov. Furthermore, the Company has organized agrochemical rail bases, a dealer network for the sale of mineral fertilizers.

Currently, PJSC KuibyshevAzot is a group of companies with the enterprises and divisions located in various regions of Russian Federation, as well as Germany, China and Serbia. There are joint ventures operating at the industrial site in Togliatti established with several of the world's largest companies.

First product from the third polyamide-6 production line.

Integrated management system was certified in compliance with international and Russian standards: ISO 9001:2000, ISO 14001:2004, and OHSAS 18001:2007.

Commissioning of engineering-plastics production at KuibyshevAzot Engineering Plastics (Shanghai) Co., Ltd. in China.

Food-grade carbon dioxide plant was started as a Joint Venture at the site of KuibyshevAzot.

Acquisition of KurskKhimVolokno LLC.

Start-up of the fourth polyamide-6 production line (textile grade).

Modification of the ammonia plant with a capacity increase to 1,800 tons per day.

Transition of technological processes to a high-pressure gas.

Soda ash production started.

Purchase of part of the property complex of Balashovsky Textile, foundation of Baltex LLC and restoration of polyamide fabric production.

Acquisition of an agrochemical depot with a railroad warehouse in Taganrog, Rostov Region.

Commissioning of a masterbatch production plant.

Acquisition of STFG Filamente GmbH (Germany), producer of textile polyamide yarn for industrial use.

Signing of a strategic partnership agreement between KuibyshevAzot PJSC and Royal DSM N.V. (the Netherlands). Within the framework of this cooperation two joint ventures were founded: engineering plastic producer — Volgaplast and trade JV — Volgalon.

KuibyshevAzot leased the spinning-drawing shop at Khimvolokno LLC (Shchekino) with the option of its subsequent buyout.

A joint venture of KuibyshevAzot PJSC and MET Development S.p.A was set up (project division of Maire Tecnimont S.p.A. (Italy)) for design and construction of urea production plant.

Start of operation of Linde Azot Togliatti LLC, a JV with German company Linde, for ammonia production.

Start-up of a nitric acid line.

Start of the fifth polyamide-6 plant.

Granulated ammonium sulphate facility has been commissioned at Granifert LLC.

An agreement signed with VEB RF on participation in the project for construction of the improved oleum and sulfuric acid production facility in the framework of Volgatechnool LLC.

A liquid nitrogenous sulfur-containing fertilizer (UAN + S) plant has been commissioned.

A joint venture established for sales of fertilizers in the Republic of Tatarstan.

Осторожно! Мошенники!

Уважаемые партнеры и потребители продукции ПАО «КуйбышевАзот»!

Информируем вас о том, что в настоящее время неизвестными лицами, выдающими себя за дилеров, дистрибьюторов, финансовых агентов или даже сотрудников ПАО «КуйбышевАзот», предпринимаются действия по вступлению в переговоры с нынешними и потенциальными клиентами с целью реализации минеральных удобрений, произведенных предприятием. Аферисты представляются от имени организаций, созвучных с названием «КуйбышевАзот», используют наименования официальных дилеров и представителей, подделывают документы, создают фальшивые сайты-копии с похожими на официальный ip-адресами и с измененными контактами и реквизитами.

Еще раз обращаем ваше внимание: достоверную информацию о дилерах, предложениях и ценах на продукцию ПАО «КуйбышевАзот» можно получить только в соответствующих разделах на официальном сайте компании www.kuazot.ru или у специалистов Управления сбыта предприятия по тел. (8482) 56-11-66, 56-17-65, 56-18-65, 56-19-65.

Если Вам позвонили, представились сотрудником «КуйбышевАзот», и на Вашем телефоне определился номер, соответствующий официальному номеру компании, обязательно наберите номер заново и убедитесь в поступившем вам предложении. Мошенники используют технические средства, «обманывающие» определитель номеров.

Внимание! «КуйбышевАзот» не работает через финансовых агентов!

Просим Вас, во избежание нежелательных последствий, проявить разумную осторожность и не пользоваться информацией о продукции ПАО «КуйбышевАзот» из непроверенных источников и от неизвестных лиц.

В случае возникновения каких-либо сомнений или вопросов относительно полученных Вами предложений или контрактов на приобретение продукции ПАО «КуйбышевАзот», настоятельно рекомендуем вам обращаться по телефонам нашей компании, указанным выше.

Пожалуйста, будьте бдительны, не позволяйте мошенникам обмануть себя!

Понятно, спасибо!